PowlSmart® Intelligent Devices

Powell has developed a suite of intelligent devices to monitor, optimize, and connect you to your equipment with real-time data 24/7 to increase uptime and electrical system reliability.

Thermal Monitoring Solutions

Today’s modern equipment designs require modern techniques and devices that not only promote safe work practices and enhance personnel safety, but also reduce operational costs associated with monitoring and maintaining your electrical equipment.

Our fiber-optic based technology provides a condition-based monitoring approach to provide 24/7 monitoring of potential hot-spot locations not visible using the traditional IR camera method. No calibration is ever required after installation at our factory.

Powell's BriteSpot® Thermal Monitoring Solution provides continuous thermal monitoring of switchgear components without compromising standard ANSI and IEC switchgear construction practices. Thousands of dollars of downtime and repair expenses are saved each year through the early detection of hot spots, while providing a system to develop real-time predictive maintenance programs for increased reliability.

BriteSpot® G3 Thermal Monitoring

Powell's BriteSpot thermal monitoring technology provides continuous thermal monitoring of switchgear components without compromising standard ANSI and IEC switchgear construction practices.

- 24/7 continuous thermal monitoring

- Direct connect installation

- Utilizes optical fiber to monitor temperature

- Utilizes backpan mounted G3 module with networking capabilities

BriteSpot® Plus Thermal Monitoring

BriteSpot Plus is a door-mounted version of our G3 thermal networking module. The panel mount display is considered the at-a-glance version for thermal monitoring providing local visibility, with alarm alerts and data immediately available to the operator.

- Door-mounted display

- Historical logging and trending

- Full networking communications

- Local LED system status indicator

Equipment Health Monitoring

Real-time monitoring of circuit breaker health, bus integrity, and environmental conditions are vital to making sure your electrical distribution system is reliable and functioning at peak performance. Powell offers a series of intelligent device solutions that provide remote monitoring and historical data collection to allow users to stay connected to their equipment 24/7 and help develop predictive maintenance internals to reduce unexpected equipment downtime and loss of productivity.

- Circuit Breaker Monitor (CBM) - provides continuous monitoring of breaker 'health' and can provide early indicators when service may be needed.

- EcoVisor - provides monitoring of environmental parameters including temperature, relative humidity and settled dust, within your equipment enclosure.

- PinPoint - provides continuous monitoring of your bus systems to help detect and locate (pinpoint) locations of partial discharge activity before a critical failure occurs.

Circuit Breaker Monitor® (CBM)

Powell's circuit breaker monitor (CBM) device is an easy-to-use, reliable method to monitor the health of your circuit breaker. The CBM device helps you shift to a predictive maintenance approach while improving your asset availability.

- Proactively monitors breaker health

- Simple green-yellow-red alert system

- Reduces unexpected downtime

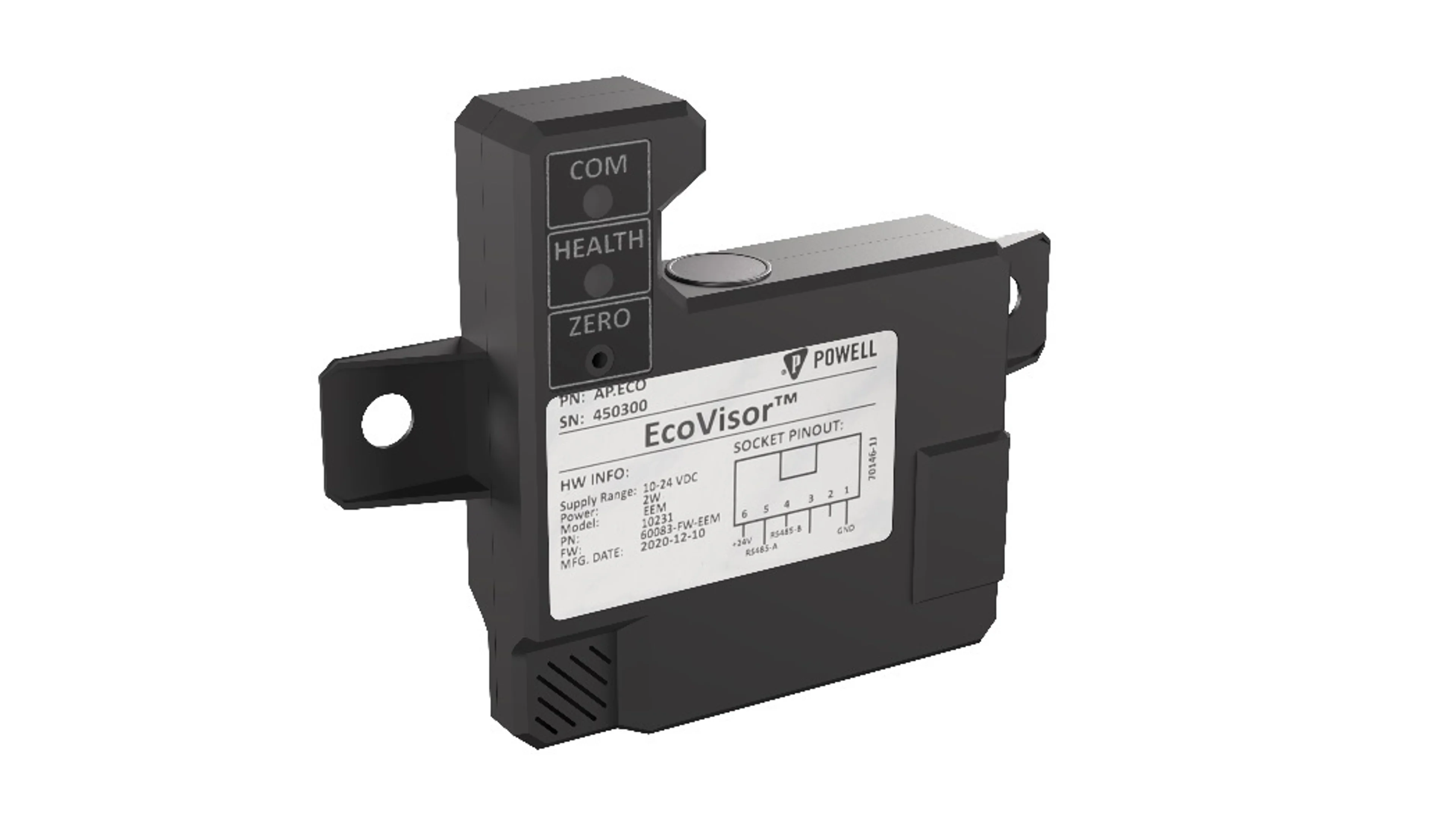

EcoVisor™

Temperature and contamination are the principal environmental factors associated with dielectric system breakdown. Powell's EcoVisor aids in the assurance of safe switchgear operation by monitoring critical environmental elements that could cause equipment failures.

- Temperature monitoring

- Relative humidity monitoring

- Settled dust monitoring

- Full communications capability

EcoVisor™ Plus

Powell's EcoVisor Plus device contains the same design features as our original EcoVisor™ device with temperature monitoring capability via our BriteSpot® technology.

- Ambient Temperature Range: -40 to +85 degrees C

- Direct Temperature Range: -50 to 200 degrees C

- Temperature Accuracy: +/- 1.5 degrees C

- Utilizes proven BritSpot thermal monitoring technology

PinPoint™

Powell's PinPoint allows you to shift toward predictive maintenance and improve asset availability by continuously monitoring for partial discharge activity within medium voltage switchgear or bus duct. The PinPoint system features a non-contact detection method using compact antennas to measure partial discharge (PD) levels. Our PD data analysis algorithms precisely identify the location of the partial discharge activity allowing personnel to take appropriate action proactively.

- 24/7 partial discharge detection and monitoring

- Non-contact detector

- PD fault detection and localization

- Increased equipment life and reliability

Motor Manager 6™

Powell's intelligent Motor Manager 6 features the most advanced microprocessor technology and a truly modular philosophy to provide the most flexible, technically advanced, and cost-effective protection, control, and monitoring functionality available.

- For LV/MV motor applications

- Diagnostic data for preventive maintenance

- Large screen with intuitive menu

- User-friendly interface

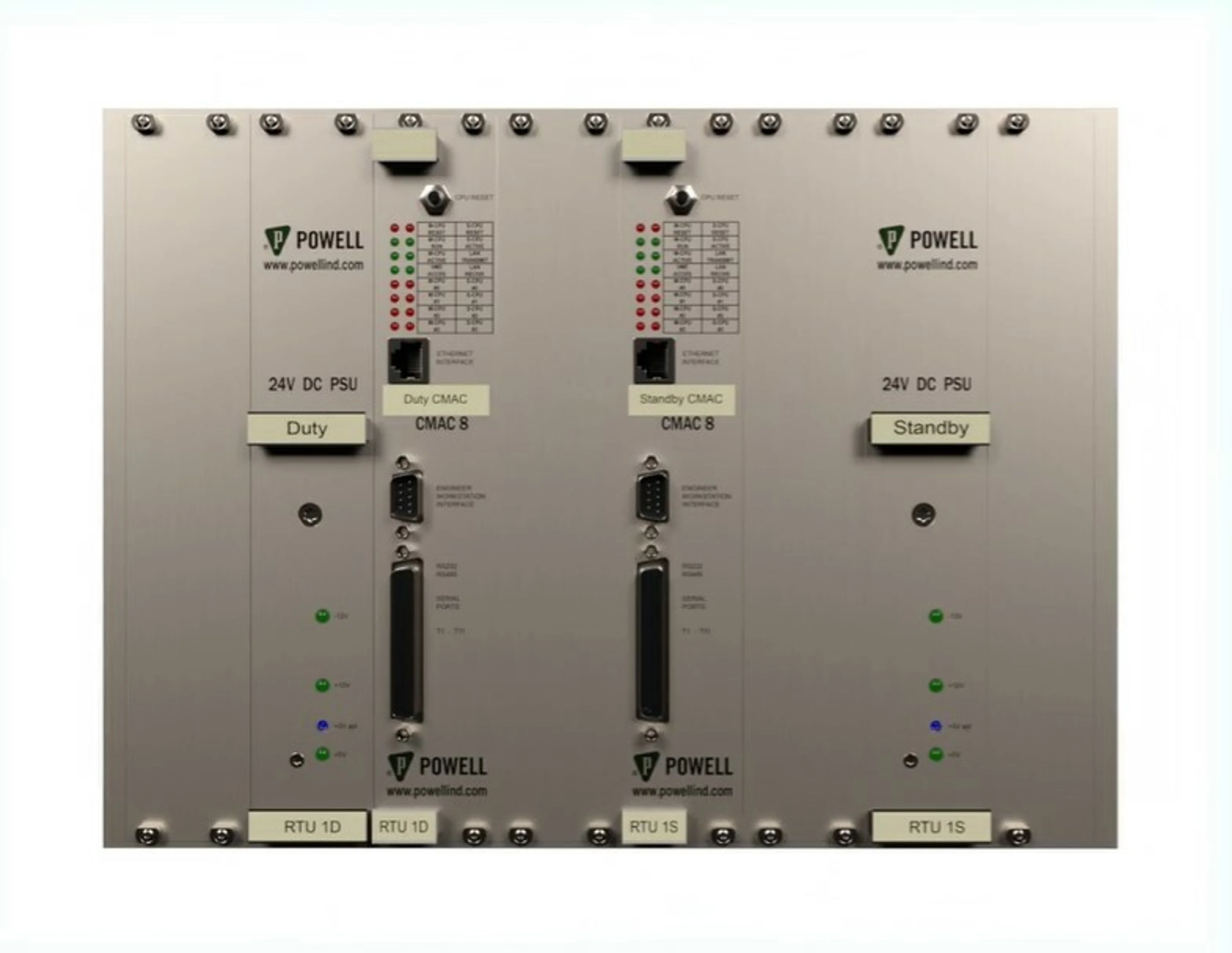

CMAC™

Our Communications Management and Control (CMAC) computer is a dedicated front-end communications processor for serially connected devices. It provides dual-redundant interfaces between the host control system and the slave devices while supporting connections from other third-party interfaces, such as IED interrogation and configuration software tools.

- Multi-protocol, multi-master information routing interface for the integration of process and electrical control system

- RS232 and RS485 serial ports

- Versa Module Europe (VME) backplane interface

- Enables interfaces to the IMS SCADA, engineering workstation, and power management system